TITANIUM PROFILE FOR MEDICAL ASTM F67

Description

Reviews

Introduction

The Titanium Profile for Medical ASTM F67 from JH-MEDICAL is manufactured from commercially pure titanium grades (GR.1–GR.4), offering excellent strength-to-weight ratio, corrosion resistance, and superior biocompatibility. Designed for use in medical and surgical devices, these profiles are produced under ISO13485 and ISO9001 certified processes, ensuring exceptional consistency and traceability. They can be customized into various cross-sectional shapes to meet the structural and functional requirements of modern medical implant systems.

Features

- Complies with ASTM F67 standard for commercially pure titanium materials.

- Available in GR.1, GR.2, GR.3, and GR.4 grades for different mechanical strength needs.

- Excellent biocompatibility and corrosion resistance suitable for long-term implantation.

- Lightweight yet high strength for reliable performance in surgical applications.

- Manufactured under ISO13485 and ISO9001 certified quality systems.

- Custom shapes and dimensions available according to customer drawings.

Product Data

| Item | Details |

|---|---|

| Product Name | Titanium Profile for Medical ASTM F67 |

| Place of Origin | China |

| Brand Name | JH-MEDICAL |

| Certification | ISO13485, ISO9001 |

| Model Number | GR.2 / GR.3 / GR.4 / GR.1 |

| Material | Commercially Pure Titanium (Grades 1–4) |

| Standard | ASTM F67 / ISO 5832-2 |

| Shape | Customized (Round / Square / Rectangular / Special Profiles) |

| Dimensions | Available as per drawing or request |

| Surface Finish | Pickled / Polished / Bright / Sandblasted (optional) |

| Mechanical Properties | Tensile strength from 240 MPa (GR.1) up to 550 MPa (GR.4) |

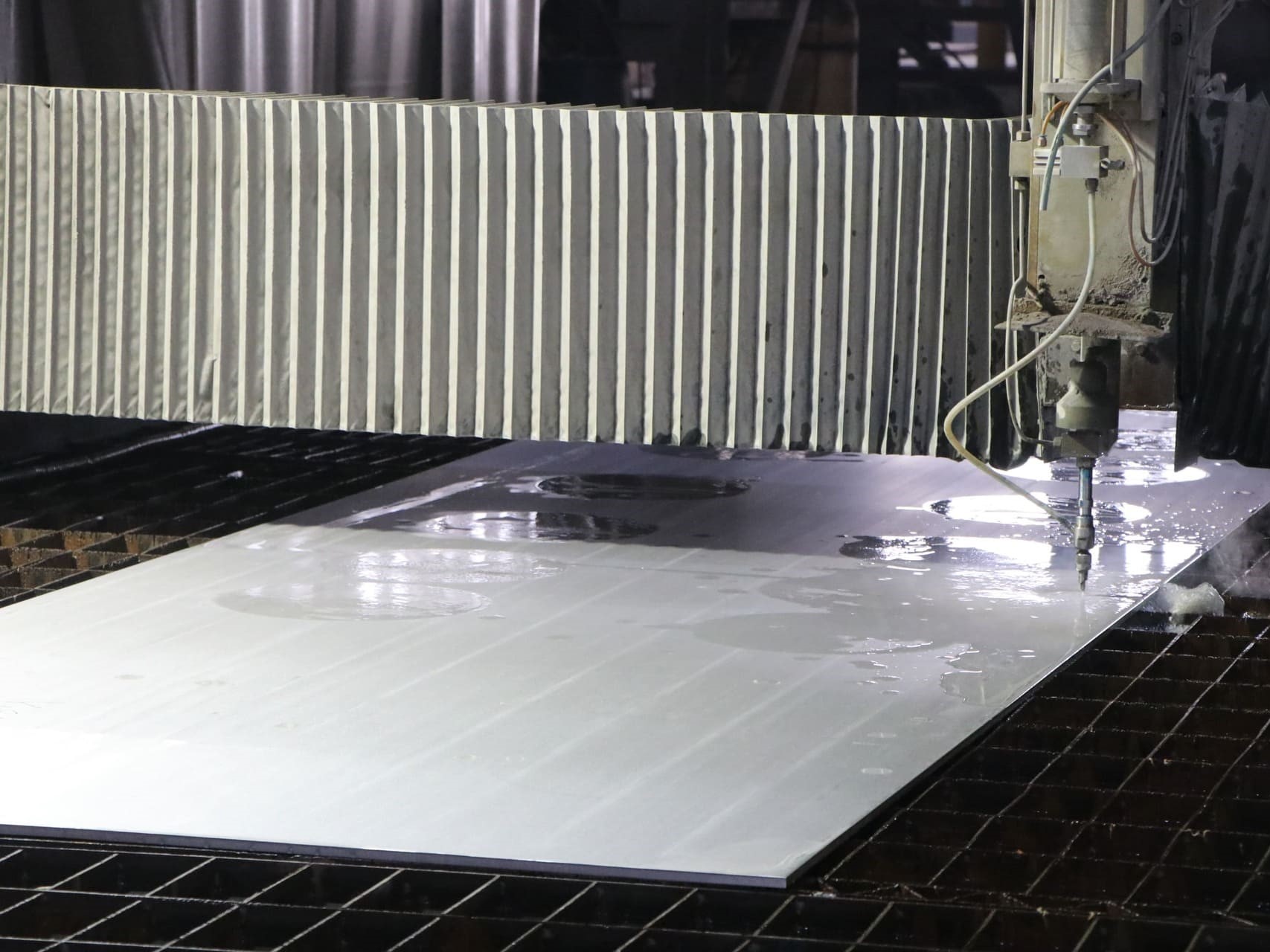

| Processing | Extrusion / Forging / CNC machining according to specifications |

| Packing | Vacuum sealed, plastic wrapped, and packed in export wooden boxes |

| Inspection & Test | Chemical analysis, mechanical testing, ultrasonic inspection, surface check |

Application

The Medical Titanium Profile is widely applied in the manufacturing of orthopedic implants, dental components, spinal fixation systems, surgical frames, and medical instrument parts. Its excellent mechanical properties and corrosion resistance ensure safety, reliability, and long-term performance in biomedical applications requiring direct contact with body tissues or fluids.