Standards: ASTM F67 / ASTM F136; ISO 5832-2 / ISO 5832-3

Grades: Grade 5 (Ti-6Al-4V); Ti-6Al-4V ELI (extra-low interstitial)

Available Sizes (mm): Ø10, Ø13, Ø14.2, Ø14.5

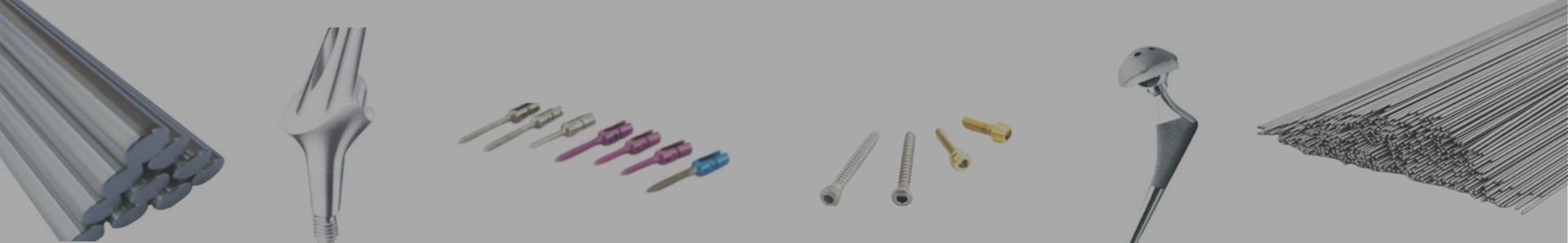

Introduction

Spinal fixation systems, including pedicle screws and rods, are essential in treating deformities, fractures, and degenerative spinal conditions. Titanium bars are commonly used as the raw material for manufacturing spine screws and related fixation components because of their excellent combination of biocompatibility, strength, and durability.

Material Standards and Medical Grades

Medical-grade titanium bars are produced to comply with internationally recognized standards such as ASTM F67/F136 and ISO 5832-2/3. These standards specify composition, mechanical requirements, and allowable impurities to ensure suitability for implantation.

Grade 5 (Ti-6Al-4V) is widely used for its high strength-to-weight ratio and fatigue resistance. Ti-6Al-4V ELI (Extra Low Interstitial) offers improved ductility and fracture toughness, making it especially suitable for critical implant applications.

Why Titanium Bars Are Ideal for Spine Screws

- Biocompatibility: Titanium forms a stable oxide layer that is well tolerated by body tissue.

- High Strength & Fatigue Resistance: Ti-6Al-4V alloys provide the mechanical reliability needed to withstand spinal loads and cyclic stress.

- Lightweight: Lower density compared with stainless steel reduces implant weight while maintaining strength.

- Corrosion Resistance: Excellent resistance to body fluids ensures long-term durability.

- Osseointegration: Titanium surface properties promote bone bonding and long-term stability of the implant.

Manufacturing Considerations

Titanium bars for spinal implants are typically produced via precision forging and CNC machining. Key manufacturing steps include:

- Raw material certification and traceability to ASTM / ISO standards.

- Hot forging or extrusion to achieve the required bar geometry and grain structure.

- CNC turning and thread cutting to form screw blanks and rods with precise tolerances.

- Surface treatments and passivation to enhance corrosion resistance and cleanliness.

- Non-destructive testing and mechanical testing (tensile, fatigue) to verify performance.

Material Characteristics

The titanium bar used for spine screws features excellent dimensional stability and precision. During the manufacturing and processing stage, the shrinkage of the material is no more than 0.05 mm, ensuring a high level of machining accuracy and consistency between batches. In addition, the metallographic structure can be precisely controlled, guaranteeing uniform grain size and optimal mechanical properties for surgical-grade applications.

Typical Applications in Spinal Surgery

Titanium-derived components manufactured from medical bars are used in a range of spinal procedures:

- Pedicle screws and locking caps for posterior fixation systems

- Connecting rods that link screw heads and maintain alignment

- Interbody cages and small connectors where titanium’s properties are advantageous

- Revision and trauma implants requiring high fatigue resistance

Size & Design Compatibility

Standard bar diameters such as Ø10, Ø13, Ø14.2 and Ø14.5 mm provide flexibility for machining different screw diameters, rod profiles, and connector geometries. Choosing the correct bar size depends on the final implant dimensions, thread profile, and machining allowances.

Clinical and Regulatory Notes

Only medical-grade titanium meeting the referenced ASTM/ISO specifications should be used for implants. Manufacturers must maintain strict material traceability, bioburden control, and regulatory documentation to comply with medical device approvals and to ensure patient safety.

Conclusion

Titanium bars — particularly Ti-6Al-4V and Ti-6Al-4V ELI produced to ASTM and ISO medical standards — form the backbone of reliable spinal fixation hardware. Their combination of biocompatibility, mechanical performance, and corrosion resistance makes them an ideal material choice for spine screws, rods, and connectors used in modern spinal surgery.

For inquiries about custom sizes, certification documents, or material test reports (MTRs), please contact our sales team.