Standards: ASTM F67 / ASTM F136 / ISO 5832-2 / ISO 5832-3

Grades: TA3, Gr3, Gr5, Ti-6Al-4V, Ti-6Al-4V ELI

Available Sizes (mm): Ø16, Ø17.2, Ø18, Ø20, Ø24, Ø30, Ø40, Ø45, Ø50, Ø55, Ø65

Characteristics: Good plasticity, high strength, excellent metallographic structure, and superior wear resistance.

Introduction

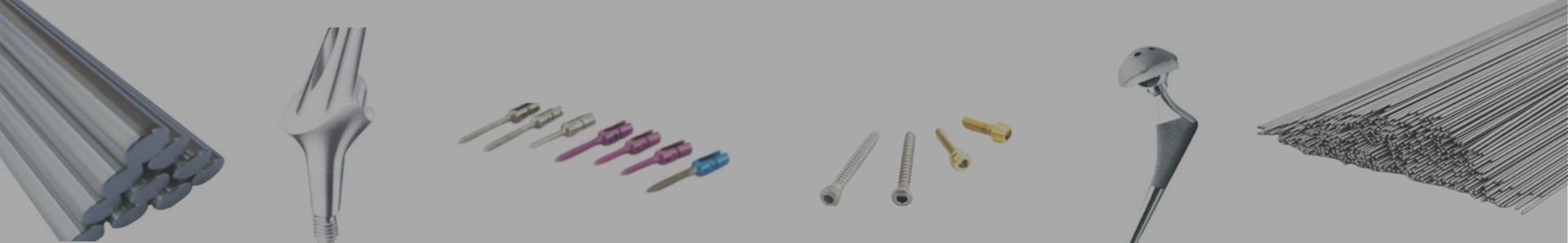

Titanium bars are among the most important materials used in the manufacturing of orthopedic implants, particularly in hip joint replacement systems. Owing to their combination of lightweight strength, plasticity, and biocompatibility, titanium bars are widely used to produce femoral stems, heads, and other structural components of artificial hip joints.

Compared with stainless steel or cobalt-chromium alloys, titanium provides excellent performance in reducing implant weight, enhancing bone compatibility, and minimizing stress shielding, thereby improving patient recovery and implant longevity.

Material Standards and Grades

Titanium bars for hip joint applications are produced according to ASTM F67 / ASTM F136 and ISO 5832-2 / ISO 5832-3 standards. These international standards ensure material purity, mechanical properties, and metallographic quality suitable for surgical use.

Common grades include TA3 (Gr3) for excellent corrosion resistance and moderate strength, and Gr5 / Ti-6Al-4V / Ti-6Al-4V ELI for high mechanical strength, toughness, and fatigue resistance, which are critical for dynamic joint motion and long-term load-bearing implants.

Key Material Characteristics

- Good Plasticity: Facilitates forging, machining, and shaping of complex implant geometries.

- High Strength: Ensures stable support and durability under long-term physiological loads.

- Excellent Metallographic Structure: Controlled grain size guarantees consistent performance and fatigue resistance.

- Good Wear Resistance: Reduces friction and debris generation at the implant interface, extending service life.

Applications in Hip Joint Implants

Titanium bars serve as the primary raw material for key components in total hip replacement systems, including:

- Femoral stems: The main load-bearing element connecting the hip head to the femur.

- Femoral heads: Spherical articulating surfaces often combined with ceramic or polymer liners.

- Acetabular cups and necks: Where precision machining and surface treatment are essential for joint mobility and integration.

The combination of high strength and good plasticity allows titanium bars to be precision forged and CNC-machined into complex implant shapes while maintaining structural integrity and biocompatibility.

Performance Advantages

Titanium’s superior elastic modulus (closer to human bone) minimizes stress shielding, while its biocompatibility promotes strong osseointegration. The material’s corrosion resistance in body fluids prevents ion release, ensuring long-term biological safety. Additionally, wear-resistant titanium surfaces reduce frictional wear at articulation points, improving implant longevity.

Manufacturing and Quality Control

The titanium bars are produced using vacuum melting, hot forging, and precision machining processes. Metallographic structure is carefully controlled during processing to achieve uniform grain size and optimal strength. Every batch undergoes mechanical testing (tensile, yield, elongation, and fatigue tests), along with ultrasonic inspection and microstructural analysis to ensure compliance with medical-grade standards.

Conclusion

Titanium bars, particularly those made from Ti-6Al-4V and Ti-6Al-4V ELI alloys, have become indispensable in the production of modern hip joint implants. With outstanding strength, ductility, and wear resistance, they ensure both mechanical reliability and biological compatibility, contributing to improved patient outcomes and long-term implant performance.

For detailed material specifications, certificates, and machining options, please contact our technical department.