Standards: ASTM F67 / ASTM F136 / ASTM F1295 / ISO 5832-2 / ISO 5832-3

Grades: TA3, TA4, GR3, GR4, GR5, Ti-6Al-4V, Ti-6Al-4V ELI, Ti-6Al-7Nb

Available Sizes (mm): Ø10, Ø20, Ø40, Ø50

Characteristics: Good physical consistency and controllable metallographic structure.

Introduction

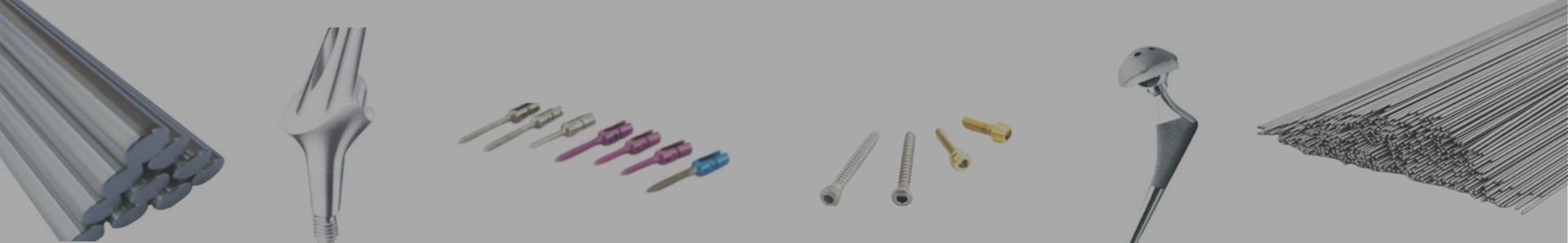

Titanium is the most widely used metal in modern dental implantology, known for its biocompatibility, high strength-to-weight ratio, and corrosion resistance. Medical-grade titanium bars serve as the raw material for manufacturing dental implant components such as implant fixtures, abutments, and healing caps. Their performance directly affects the safety, stability, and longevity of the final implant system.

Material Standards and Grades

Titanium bars for dental applications must comply with stringent international medical standards to ensure biological safety and mechanical reliability. Common specifications include ASTM F67 (unalloyed titanium for surgical implant applications), ASTM F136 (Ti-6Al-4V ELI), ASTM F1295 (Ti-6Al-7Nb), and ISO 5832-2/3.

These grades cover both commercially pure titanium (Grade 3 and Grade 4) — valued for corrosion resistance and osseointegration — and titanium alloys such as Ti-6Al-4V, Ti-6Al-4V ELI, and Ti-6Al-7Nb, which provide higher strength and fatigue performance for advanced implant systems.

Why Titanium Is Ideal for Dental Implants

- Excellent Biocompatibility: Titanium’s natural oxide film prevents chemical reactions with body tissues, minimizing the risk of rejection or inflammation.

- Osseointegration: The surface of titanium promotes direct bonding with bone tissue, ensuring long-term implant stability.

- High Strength and Fatigue Resistance: Alloys such as Ti-6Al-4V and Ti-6Al-7Nb maintain mechanical reliability under the repetitive loads of chewing.

- Corrosion Resistance: Titanium withstands saliva and other oral fluids, ensuring implant durability for decades.

- Lightweight and Non-Magnetic: Titanium’s low density and non-magnetic nature make it comfortable and safe for daily life and medical imaging.

Material Characteristics and Processing

The titanium bar used for dental implants exhibits good physical consistency and a controllable metallographic structure. These properties ensure stable machining performance, uniform microstructure, and predictable mechanical behavior after precision forging or CNC processing. Typically, the microstructure is optimized to achieve the ideal balance of strength, ductility, and fatigue resistance.

Advanced manufacturing techniques such as vacuum melting, hot forging, ultrasonic testing, and surface passivation are employed to guarantee material purity and consistency, meeting strict medical device standards.

Applications in Dental Implant Systems

Titanium bars are used to produce a variety of critical components in dental systems:

- Implant fixtures (root-shaped anchors inserted into the jawbone)

- Abutments connecting the implant and the prosthetic crown

- Healing abutments and surgical tools

- Customized implant structures for digital or CAD/CAM systems

The combination of strength, biocompatibility, and precision ensures the reliability of each part, allowing dental professionals to achieve stable osseointegration and long-term success in implant treatment.

Quality Control and Certification

Each batch of titanium bars undergoes comprehensive inspection, including mechanical testing (tensile, yield, elongation), metallographic analysis, and ultrasonic flaw detection. Full traceability is maintained in compliance with ISO and ASTM standards, and certified Material Test Reports (MTRs) can be provided upon request.

Conclusion

Titanium bars are the foundation of modern dental implant manufacturing. With excellent consistency, biocompatibility, and mechanical performance, they ensure both patient safety and clinical effectiveness. Whether made from pure titanium or advanced titanium alloys like Ti-6Al-7Nb, these materials continue to drive innovation and reliability in oral implantology.

For more details on specifications, machining options, or medical certifications, please contact our engineering team.