Standards: ASTM F136 / ASTM F67 / ISO 5832-2 / ISO 5832-3 / ISO 5832-11

Grades: Gr5, Ti-6Al-4V, Ti-6Al-4V ELI, Ti-6Al-7Nb

Available Sizes (mm): Ø0.8, Ø1.0, Ø1.2, Ø2.0, Ø3.0, Ø4.0

Characteristics: Surface roughness ≤ 0.8 μm, suitable for Kirschner wire, elastic intramedullary nail, and other orthopedic applications.

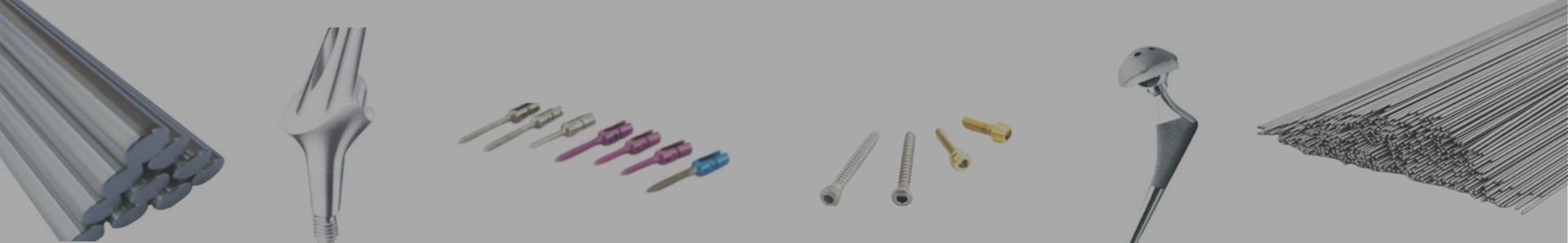

Introduction

Medical titanium wire is a critical raw material used in orthopedic, dental, and surgical implant manufacturing. Known for its combination of high strength, excellent elasticity, and superior biocompatibility, it serves as an ideal choice for load-bearing and flexible fixation components such as Kirschner wires (K-wires) and elastic intramedullary nails.

Material Standards and Composition

The production of medical titanium wire complies with international medical material standards, including ASTM F136 (Ti-6Al-4V ELI), ASTM F67 (commercially pure titanium), and ISO 5832-2/3/11. These specifications define purity, mechanical properties, and metallographic requirements to ensure reliability in surgical use.

Common grades include Gr5 (Ti-6Al-4V) and Ti-6Al-4V ELI for high-strength, fatigue-resistant applications, as well as Ti-6Al-7Nb for enhanced corrosion resistance and biocompatibility in advanced implant systems.

Key Features and Advantages

- High Elasticity: Allows controlled flexibility and deformation without fracture, essential for intramedullary fixation devices.

- Superior Strength: Withstands cyclic loads and bending forces in dynamic orthopedic environments.

- Biocompatibility: Titanium’s natural oxide film ensures compatibility with human tissues and prevents rejection.

- Precision Surface: Finished with surface roughness ≤ 0.8 μm, ensuring smoothness for insertion and minimizing tissue irritation.

- Corrosion Resistance: Stable in body fluids, ensuring long-term implant performance.

Applications in Medical Devices

Titanium wire is widely used across multiple medical disciplines due to its flexibility and mechanical integrity. Typical applications include:

- Kirschner wires (K-wires): Used for temporary fixation of bone fractures and small bone alignment.

- Elastic intramedullary nails: Applied in pediatric and adult fracture treatment for flexible internal fixation.

- Orthodontic wires: Used in dental alignment systems where resilience and corrosion resistance are critical.

- Surgical sutures and guide wires: Requiring high ductility and consistent surface finish.

Manufacturing and Quality Control

Medical titanium wire is produced through precision drawing, annealing, and surface polishing processes under controlled conditions. Metallography is carefully monitored to achieve a uniform grain structure, ensuring consistent mechanical properties and elasticity. Each batch is tested for tensile strength, elongation, microstructure, and surface roughness to meet implant-grade standards.

Conclusion

Highly elastic and high-strength medical titanium wire provides the perfect balance of flexibility and reliability for surgical and orthopedic applications. Manufactured in compliance with ASTM and ISO standards, it ensures patient safety, superior performance, and long-term clinical success in bone fixation, dental correction, and implant systems.

For detailed specifications, machining options, and certification documents, please contact our technical department.