Leading Supplier of Medical Titanium Materials

Innovation and Quality!

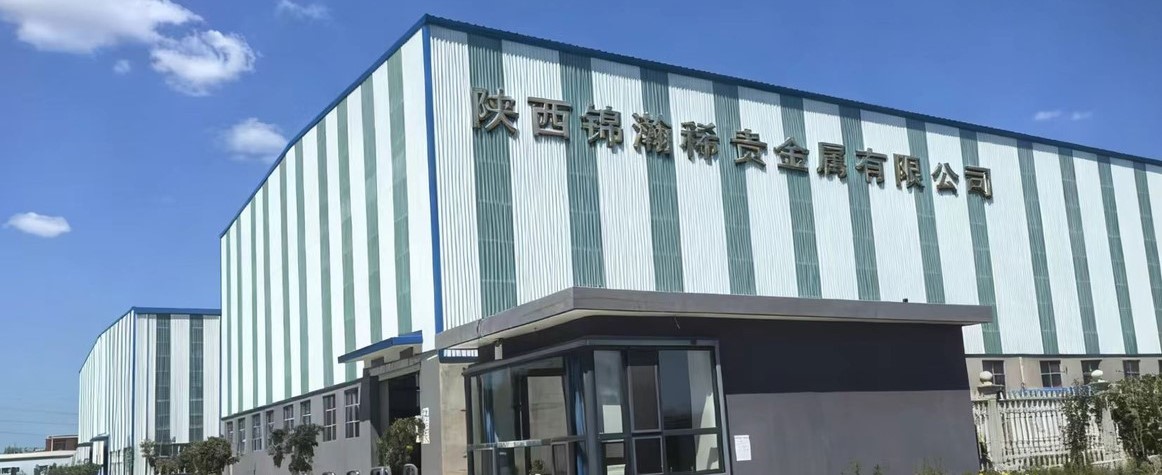

Shaanxi Jinhan Rare Precious Metals Co.,Ltd, founded in 2009, is a wholly owned subsidiary of Baoji Jinshan Titanium Industry. We are dedicated to the research, development, production, and sales of medical titanium materials.

Medical-grade titanium offers excellent biocompatibility and mechanical stability, making it ideal for orthopedic and dental implants. It helps reduce rejection reactions and supports precision medicine.

From melting and forging to precision machining, we have established a complete industrial chain layout. With continuous dedication and innovation, we strive to become a global leader and professional supplier of medical titanium materials.

3,000+Tons

Annual output

60+

No. of Employees

8000W+USD

Annual Sales

80%+

Export P.C

2009

Year Established

1000+

Customers Served

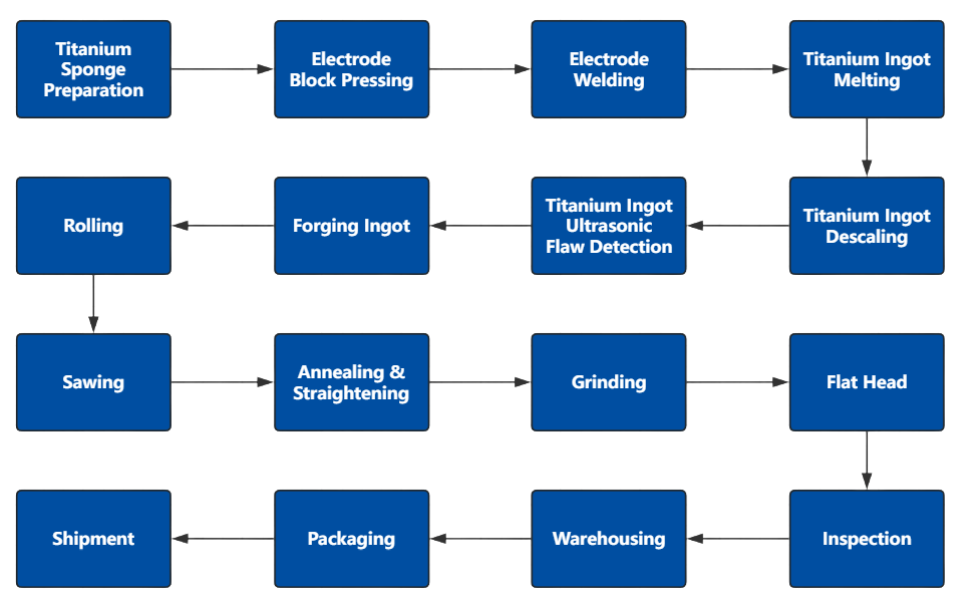

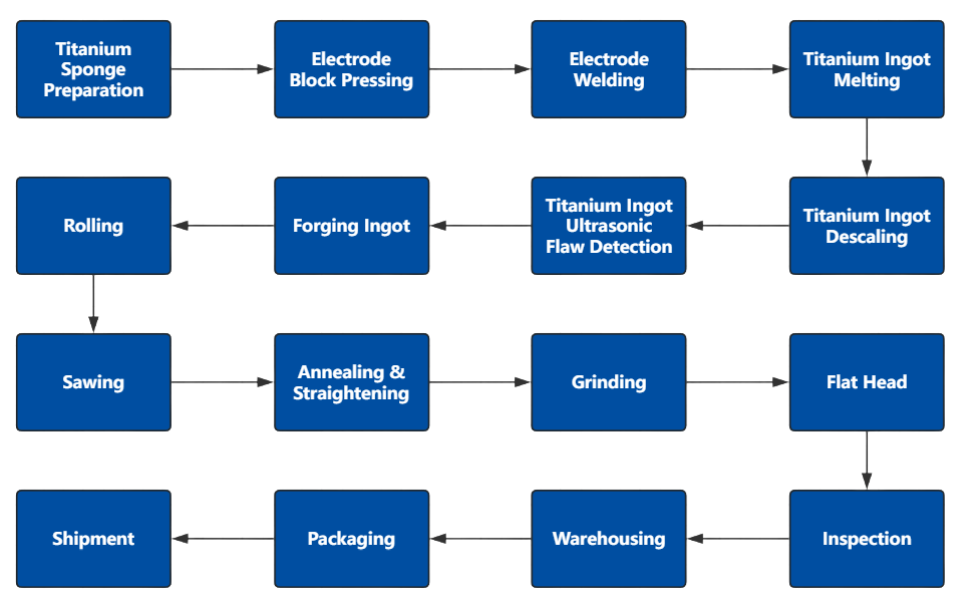

JH Production Process

JH Production Base

JH has built a complete titanium processing chain - from raw material smelting to forming and quality inspection. Backed by rich titanium resources and a stable supply of high and purity ingots, the company ensures consistent quality and fast delivery. Its advanced facilities include automatic vacuum self-consumption electric arc furnaces, wire rod rolling mill, automatic rotary head ultrasonic flaw detector, optical surface automatic detector, and precision grinding equipment. These technologies enable JH to produce medical-grade titanium materials with exceptional surface finish, mechanical stability, and biocompatibility, meeting the strict standards required for orthopedic, dental, and surgical applications, while also serving select industrial needs.

4500 tons hydraulic press

Annealing straightening line

Automatic mixing machine

CNC grinding machine

Sawing machine

Skinning production line

Surface inspection

Ultrasonic automatic inspection line

VAR furnace

Vacuum Arc Remelting Furnace

-

FAC (Full-Automatic Control) — From arc start to shrinkage, the entire melting process is fully automated, minimizing human intervention and ensuring stable ingot quality throughout production.

-

MCD (Multicontact Conductive Design) — The melting process adopts a fully coaxial power supply, effectively eliminating the adverse effects of induction magnetic fields on alloy quality and significantly improving electrical efficiency.

-

DDS (Dual Motor Drive System) — This system ensures precise electrode feeding control during melting, promoting the desired physicochemical reactions and resulting in superior ingot surface quality.

-

SCR (Semiconductor Control Rectifier Power Supply) — SCR power supply provides high-precision melting power control with stable current and voltage, achieving consistent composition, minimal porosity, and a dense crystalline structure.

-

CSS (Constant Melting Speed Control System) — Enables multiple control modes, including voltage control, constant melting speed, and short-circuit control for melt drops, ensuring process flexibility and precision.

-

DAS (Data Acquisition System) — A powerful monitoring platform that supports fully automatic process recording and comprehensive data analysis, enhancing traceability and process optimization.

-

SCS (Smelting Pressure Control System) — Maintains optimal pressure to reduce volatilization of low-melting-point elements, improving alloy stability.

-

AEP (Automatic Emergency Protection Program) — A comprehensive safety control mechanism that automatically activates emergency protection procedures in the event of unexpected situations such as water or power failure, ensuring safe and reliable operation.

JH Medical Titanium Customers

JH Advantages

①

Raw material

All of our products are made with 0A grade titanium sponge.

②

Technical process

Three times of smelting makes the material purer, more uniform and consistent. Combined with over ten thousand batches of chemical composition, physical properties, product inspection and other databases, it provides high-quality products for the medical field.

③

Process control

The production equipment is equipped with an online automatic inspection system, and strict five-inspection procedures are followed to ensure the traceability of the delivered products. This includes temperature control data collection, hole size collection, infrared diameter data collection, and ultrasonic surface inspection. It also further reduces manual intervention and improves batch stability.

④

Advanced equipment

Automatic mixing system and the world's leading melting furnaces, which overcome the metallurgical defects that may occur compare with other similar equipment. This enhances the stability of material batches and extra low interstitial.

JH Quality

JH currently has over 60 employees, among whom the quality team consists of 9 members, accounting for 15%. All have a master's degree.

JH to quality is built around the following best practices :

Quality is a priority for us

-

CULTIVATE THE IMPORTANCE OF CUSTOMER SERVICE AMONG OUR PERSONNEL AND DEVELOP THEIR EXPERTISE

-

ANSWER OUR CUSTOMERS’ QUALITY AND DELIVERY REQUIREMENTS

-

SEEK CONTINUOUS IMPROVEMENT IN THE FOLLOWING AREAS ; PROCESS EFFICIENCY, CAPACITY TO PROVIDE EXPERTISE, QUALITY, COMPETITIVITY AND MATERIAL AVAILABILITY

-

COOPERATE WITH MANUFACTURERS AND CUSTOMERS TO CREATE SYNERGIES AND SHARE KNOWLEDGE AND RESOURCES TO ADEQUATELY COMPLY WITH EVER EXPANDING REGULATORY AND TECHNICAL REQUIREMENTS

Please do not hesitate to reach out to us for any further quality related information you may need. You can address your queries to the following email :

qualite@jhtitanium.com

_1761186579_WNo_1599d1066.jpg)

_1760583540_WNo_1200d1697.jpg)

_1760583569_WNo_1200d1697.jpg)

_1760583601_WNo_1200d1642.jpg)